Download our catalog

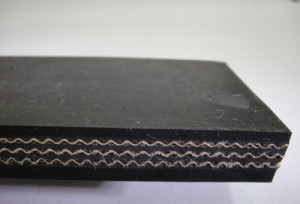

High Abrasion Resistant Conveyor Belting – HARK

Conveyor belting designed for the ultimate resistance to abrasion. Equivalent to DIN-W grade with less than 90 Cu.mm abrasion loss and DIN-Y with less than 80 Cu.mm abrasion loss, these conveyor belts are developed to assure you of the longest belt lifetime. The combination of polyester in warp and nylon infilling provides technical low-stretch, high impact abuse resistance. Recommended for transporting abrasive materials, such as glass, cullet, granite, trap rock, etc.

| Fabric / Ply | 3P | 4P | 5P | 6P |

|---|---|---|---|---|

| NN – 135 | 360 | 480 | 600 | 720 |

| NN – 160 | 450 | 600 | 750 | 900 |

| NN – 200 | 600 | 800 | 1,000 | 1,200 |

| NN – 250 | 750 | 1,000 | 1,250 | 1,500 |

| NN – 300 | 900 | 1,200 | 1.500 | 1,800 |

| NN – 350 | 1,050 | 1,400 | 1,750 | 2,100 |

| NN – 400 | 1,200 | 1,600 | 2,000 | 2,400 |

| EP – 135 | 375 | 500 | 625 | 750 |

| EP – 160 | 450 | 600 | 750 | 900 |

| EP – 200 | 600 | 800 | 1,000 | 1,200 |

| EP – 250 | 750 | 1,000 | 1,250 | 1,500 |

| EP – 300 | 900 | 1,200 | 1,500 | 1,800 |

| EP – 350 | 1,050 | 1,400 | 1,750 | 2,100 |

| EP – 400 | 1,200 | 1,600 | 2,000 | 2,400 |

| Cover Grade | Tensile Strength Min (Mpa) |

Elongation Min (%) |

Abrasion Loss Max (mm2) |

|---|---|---|---|

| DIN-W | 18 | 450 | 90 |

| DIN-Y | 20 | 450 | 110 |

| GRADE 1 | 17 | 450 | 120 |

| GRADE 2 | 14 | 400 | 170 |

| GRADE 1 HARK | 18 | 450 | 90 |

| MOR | 12 | 1,400 | 300 |

| SOR | 15 | 300 | 200 |

| FABRIC TYPE | |||

| NN | Nylon / Nylon | ||

| EP | Polyester / Nylon | ||

| SW | Straight Wrap | ||

| CFW | Crow Foot | ||

| BREAKER FABRIC | Steel Mesh | ||

Fire Retardant Conveyor Belting – FR Rubber

Fire retardant conveyor belting designed for the service conditions of the mining industry. Suitable for mining, power plants, electric utilities, and coal cleaning plants. Different rubber compounds are available to meet your requirements.

| Type | Cover Rubber | Special Features | |||

| Min Tensile Strengh | Min. Elongation % |

Application Grade |

|||

| Kg/cm2 | psi | ||||

| MSHA-14 | 140 | 2,100 | 400 | M-14 | Neoprene cover fire retardant static conductive, self-extinguishable covers meeting MSHA-14. |

| MSHA-18 | 150 | 2,200 | 400 | M-18 | SBR fire retardant cover rubber meeting MSHA-18. |

| CAN-CSA-C | 150 | 2,200 | 400 | CSA-C | SBR fire retardant cover rubber meeting CAN-CSA and low temperature. |

| SCORF | 170 | 2,400 | 400 | MOR/MSHA (USA) | Oil treated coal and grain industries requiring fire and oil retardant, static conductivity with lower electric resistance. |

M – 18 grade is an SBR fire retardant cover rubber meeting MSHA – 18 standards. It provides resistance to wear and cold temperatures.

SCORF grade is fire resistant with medium oil resistance and accepted by MSHA. It is recommended for typical applications such as oil treated coal and grain industries requiring fire & oil resistance, and static conductivity with lower electric resistance.

Fire Retardant Conveyor Belting – FR PVC

- Width – 750 mm to 1830 mm (30” to 72”)

- Type – 3500 PIW to 15000 PIW (610 kN/m to 2625 kN/m)

- Covers – FRAS PVC (Up to 3.0 mm)

- Special Covers – On offer for abrasion, heat and oil resistance

- Roll Length – As required by customer subject to shipment restrictions by road and sea

- Color – Black. However, special colored PVC covers can be made on request

- Special Weave Constructions – load impact bearing, high-tear, and rip resistant

| Type | Warp | Weft | Nominal Belt Thickness | Nominal Belt Weight | Minimum High Tension Drum Diameter |

Minimum Low Tension Drum Diameter |

|---|---|---|---|---|---|---|

| (lbs/in) | (kN/m) | (kN/m) | (mm) | (kg/m2) | (mm) | (mm) |

| 250 | 44 | 25 | 6.5 | 9.0 | 250 | 225 |

| 350 | 63 | 26 | 8.0 | 10.5 | 400 | 315 |

| 450 | 80 | 35 | 8.5 | 11.0 | 500 | 355 |

| 500 | 87 | 35 | 9.0 | 11.2 | 500 | 355 |

| 600 | 100 | 35 | 9.3 | 12.0 | 630 | 400 |

| 650 | 114 | 35 | 9.5 | 12.2 | 630 | 400 |

| 800 | 140 | 35 | 11.5 | 14.0 | 750 | 450 |

| 900 | 160 | 42 | 12.0 | 15.0 | 800 | 600 |

| 1,000 | 180 | 45 | 13.0 | 16.2 | 800 | 600 |

| 1,200 | 210 | 45 | 14.0 | 18.0 | 1000 | 750 |

| 1,500 | 262 | 45 | 15.5 | 19.5 | 1250 | 800 |

- ISO 9001:2008 (Global) Certified.

- Directorate General Of Mines Safety (DGMS) approval as per IS 3181:1992.

- Mine Safety and Health Administration approval as per US-MSHA, Title 30 of Code of Federal Regulations (CFR).

- Canadian Standards Authority approval as per CSA-M422-14 Type A-1

Heat Resistant Conveyor Belting – HR

Performance proven heat resistant conveyor belting recommended to protect conveyor belting from surface cracking and hardening by heat from hot service applications like hot sintered ore, hot pellet, hot clinker, hot chemical, fertilizer and hot cement, etc. Heat and abrasion resistant cover rubber has been heat treated and dipped to minimize carcass shrinkage and heat aging.

| Temperature | Type | Compound of Cover Rubber | Termperature of Material Carried | Application | |

| Peak material Temp. for sort period (ºF) |

Cont. material Temp. (ºF) |

||||

| Medium Temperature |

HR-400 | EPDM | Lump 400ºF Fines 300ºF |

Lump 350ºF Fines 200ºF |

For medium temperature applications(castings, sintered ore, coke, limestone). |

| High Temperature |

HR-700 | EPDM | Lump 650-700ºF Fines 450-500ºF |

Lump 550-600ºF Fines 300-400ºF |

For higher temperature use(dried clay, cement clinker, etc.) |

| Super Temperature |

HR-850 | EPDM/EPM | Lump 800-850ºF Fines 600-650ºF |

Lump 700-750ºF Fines 500-550ºF |

For super high temperature application.(sintered ore, cement clinker, chemicals etc. |

| Materials Carried | Lump Size | Termperature of Material Carried | Belt Surface Temperature |

|---|---|---|---|

| Sintered Ore | 25-200 mm (1-8 inch) | 200-400ºC (390-750ºF) | 130-150ºC (270-300ºF) |

| Return of Sintered Ore | Below 10 mm (0.4 inch) | 260ºC (480ºF) | 150-190ºC (300-370ºF) |

| Coke | 100-200 mm (4-8 inch) | 70-100ºC (160-210ºF) | 50-60ºC 120-140ºF) |

| Raw Material | Below 30 mm (1.2 inch) | 180-220ºC (360-410ºF) | 100-120ºC (210-250ºF) |

| Clinker | 10-30 mm (0.4 – 1.2 inch) | 100-220ºC (210-440ºF) | 100-110ºC (210-230ºF) |

| Cement | Powder | 100-125ºC (210-250ºF) | 80-90ºC (170-190ºF) |

| Metal Powder | – | 170ºC (340ºF) | 120-130ºC (250-270ºF) |

| Molding Sand | – | 200-250ºC (390-480ºF) | 80-90ºC (170-190ºF) |

Heat resistant belts are best suited for conveying product that is over 60º (140º F). The surface temperature of heat resistant belting varies with the material type, belt speed, loading rate and size. To select the proper heat resistant belting, consider not only the material temperature to be conveyed but the surface temperature of the belt as well.

Oil Resistant Conveyor Belting – OR

Belting with cover rubber compounded for applications requiring resisitance to oils. Outstanding abrasion, ozone and weather resistance. Recommended for conveyor lines prone to swelling and sponginess due to contact with oils.

| Type | Cover Rubber | Use | |||

| Min Tensile Strengh | Min. Elongation% | Volume ChangeASTM #3 Oil | |||

| Kg/cm2 | psi | ||||

| SOR | 160 | 2,250 | 500 | Max 20 | Oily metal parts, crushed soybeans, automatic hydrocarbons such as benzol, toulene,& petroleum based oils. |

| OR-200 | 120 | 1,700 | 500 | Max 90 | Oil treated materials and for carrying oily metal turnings and shavings, crushed soybeans, animal or vegetable fats. |

| MOR | 140 | 2,000 | 450 | Max 150 | Wood chip, linseed, cottonseed, kernel corn, and whole soybeans. Static conductivity, and moderate oil resistance. |

| HOT ASPHALT | 120 | 1,700 | 500 | Max 60 | Hot asphalt, coke whafs, and other oil & heat resistant applications. |

OR-200 grade has superior oil resistance to various kinds of animal and vegetable oil with cold temperature.